Remembering a Titan

/Written by Arthur Neal, FGIS Deputy Administrator

“Who is this guy that keeps emailing me all of these questions?” is what I asked myself and staff, as I had not, yet, started my new role as the Deputy Administrator for the U.S. Department of Agriculture’s Federal Grain Inspection Service (FGIS). Still transitioning out of my role as the Deputy Administrator for Transportation and Marketing, I quickly began to learn about a man named Tom Dahl.

As FGIS staff began to give me background on Tom, I figured, I’d better give him a call just to introduce myself. Once introduced by phone, I let Tom know that I had to take a trip to Iowa to close out some business for my former program area, and if he’d like, we could meet for an hour to get to know one another.

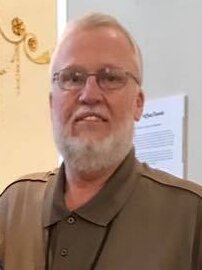

Tom agreed to meet me in the lobby of my hotel in Des Moines. Once I arrived, I spotted him immediately. He stood tall, smiled big, and spoke with authority. Little did I know that a one-hour meeting would turn into a three-hour meeting! Tom shared so much in that time. He gave me an orientation about the American Association of Grain Inspection and Weighing Agencies, he told me about Sioux City Inspection & Weighing Service, he gave me a history lesson about FGIS, he let me know about a host of issues that needed to be addressed, he told me about the Grain Inspection Advisory Committee and more. However, it’s not what Tom “told” me that stuck with me. It’s how Tom shared during the encounter.

Tom shared from a place of authenticity, respect, concern, and passion. He shared stories about his upbringing, his family, his relationships, his joys, his pains, as well as his hopes for grain inspection. He shared his heart, an experience I would learn, overtime, is one of the things that makes him special. As we drew near to the third hour of engagement, I told Tom, “Hey, man…I have other people I have to meet with. I can’t spend all my time with you!” We laughed, shook hands, and knew that the ensuing journey we were about to embark would be productive, collaborative, respectful, and encouraging.

We’re still on the journey. The foundation has been laid. There continues to be much work to do. And the infectious smile, as well as the booming presence and voice of Tom Dahl is still felt and heard throughout the hallways of our hearts to inspire us along the way!

On behalf of the FGIS team, we salute you, Tom!